En el dinámico mundo de la gestión de residuos y el reciclaje, la eficiencia, el control de costes y la calidad de los materiales son fundamentales. Para las empresas que gestionan volúmenes significativos de papel (papel de caja abierta, papel mixto, papel de oficina) y plásticos rígidos/semirígidos (HDPE, botellas de PET, contenedores, paquetes de film), las empacadoras horizontales se convierten en herramientas indispensables, ofreciendo un conjunto de ventajas convincentes sobre métodos alternativos como las empacadoras verticales o la manipulación manual. A continuación, se detallan sus principales ventajas:

1. Rendimiento y reducción de volumen inigualables:

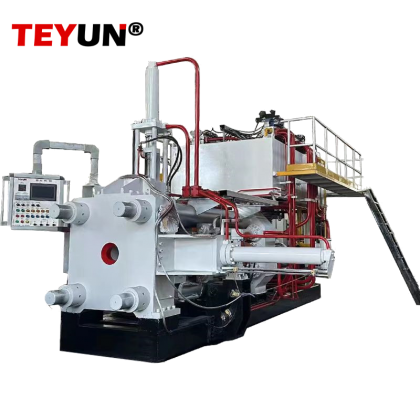

Procesamiento de alta capacidad: Las empacadoras horizontales están diseñadas para un funcionamiento continuo de gran volumen. Pueden procesar cantidades de material mucho mayores por hora que las empacadoras verticales. Imagine camiones llenos de cajas de cartón sueltas o fardos de botellas de plástico alimentados en un flujo constante mediante una cinta transportadora o una carretilla elevadora.

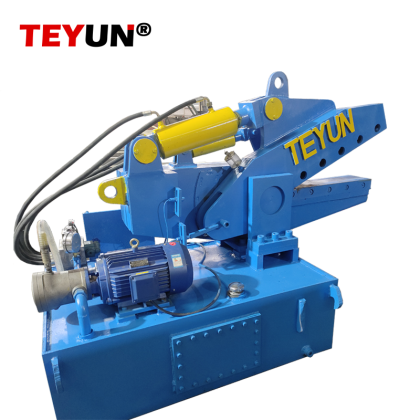

Densidad Extrema: Sus potentes cilindros hidráulicos ejercen una enorme presión (a menudo de cientos de toneladas) en un recorrido largo y horizontal. Esto tritura las bolsas de aire y comprime el material con mucha mayor eficacia que las empacadoras verticales. ¿El resultado? Pacas excepcionalmente densas y compactas. Esta densidad es crucial:

Ahorro en transporte: Cabe más material en cada carga de camión. El transporte aéreo es caro; el envío de pacas compactas reduce drásticamente los costos de flete.

Eficiencia de almacenamiento: Los fardos densos requieren significativamente menos espacio en almacenes, patios o contenedores de envío.

Mayor valor: los recicladores a menudo pagan primas por fardos de alta densidad de manera constante, ya que rinden más materia prima por pie cúbico y procesan de manera más eficiente en la MRF (instalación de recuperación de materiales).

2. Eficiencia y seguridad laboral significativas:

Reducción de la manipulación manual: Las empacadoras horizontales minimizan la necesidad de que los trabajadores compacten manualmente el material en una cámara. La carga se realiza generalmente mediante sistemas transportadores o montacargas que vierten el material en una tolva de gran tamaño. Esto reduce drásticamente las tareas físicamente exigentes y potencialmente peligrosas de empujar, compactar y compactar el material.

Atado y expulsión automáticos: Una vez comprimida, la paca se ata automáticamente con múltiples alambres o correas. A continuación, la paca completa se expulsa horizontalmente y con suavidad sobre una cinta transportadora o el suelo mediante un cilindro de expulsión motorizado. Esto elimina el peligroso proceso manual de retirar pacas pesadas de una cámara vertical.

Operación más segura: Los operadores interactúan con la máquina principalmente desde un panel de control, lejos de las zonas de compresión y expulsión. Los enclavamientos de seguridad, las protecciones y los modernos sistemas de control minimizan aún más los riesgos asociados con la operación de maquinaria pesada.

3. Manejo de materiales y logística optimizados:

Integración de la cinta transportadora: Las empacadoras horizontales están diseñadas para integrarse a la perfección con los sistemas de transporte, tanto aguas arriba (alimentación de material suelto) como aguas abajo (desplazamiento de pacas terminadas). Esto crea un flujo de material fluido y continuo, reduciendo los cuellos de botella y las transferencias manuales.

Tamaños de pacas estandarizados: Producen pacas grandes y uniformes (p. ej., tamaños estándar de fábrica como 152 cm x 76 cm x altura variable para papel, o tamaños personalizados para plásticos). Esta estandarización simplifica la logística de apilado, almacenamiento y transporte. Las carretillas elevadoras pueden manipular y mover fácilmente estas unidades predecibles y estables.

Ventaja específica para plásticos: En el caso de plásticos rígidos, la alta presión rompe eficazmente artículos voluminosos como botellas y contenedores, maximizando la densidad y evitando el rebote elástico que afecta a las máquinas menos potentes. Para plásticos en película (a menudo preempacados), las empacadoras horizontales crean pacas densas y manejables, mucho menos propensas a desenrollarse o engancharse.

4. Mejora de la calidad y comercialización de las pacas:

Consistencia: Los procesos automatizados y la potente compresión garantizan la consistencia de la densidad, la forma y el peso de las pacas. Esta previsibilidad es muy valorada por las plantas de reciclaje y los intermediarios.

Riesgo de contaminación reducido: Los sistemas de alimentación eficientes (como precompactadores o fondos vivos) y el funcionamiento continuo minimizan la posibilidad de que materiales no deseados queden atrapados o creen puntos débiles en el fardo en comparación con los métodos de carga manual.

Unión más firme: Múltiples alambres o correas de alta resistencia sujetan firmemente la paca compacta durante la manipulación y el transporte, evitando la desintegración y la pérdida de valor del material. Esto es especialmente crucial para los plásticos, que pueden ser más resbaladizos y propensos a moverse.

5. Eficiencia espacial (en relación con la producción):

Aunque físicamente más grandes que las empacadoras verticales, las empacadoras horizontales generan una producción de material compactado significativamente mayor por metro cuadrado de superficie ocupada. La enorme reducción de volumen lograda significa que el espacio que liberan para almacenamiento y transporte supera con creces su tamaño. Representan un uso altamente eficiente del valioso espacio industrial.

Las empacadoras horizontales no son simples máquinas; son activos estratégicos para cualquier instalación que procese volúmenes considerables de papel o plástico reciclable. Sus principales ventajas

–

Alto rendimiento, densidad extrema, eficiencia laboral y de seguridad, logística optimizada y calidad de paca superior.

–

Se traducen directamente en beneficios tangibles: reducción de costos de transporte, minimización de las necesidades de almacenamiento, menores gastos de mano de obra, mayor seguridad de los trabajadores y maximización de los ingresos derivados de los materiales reciclables. Si bien requieren una mayor inversión inicial y un mayor espacio que las empacadoras verticales, su eficiencia operativa y ahorro de costos las convierten en las líderes indiscutibles para operaciones de reciclaje de papel y plástico a gran escala, rentables y sostenibles. Son los motores invisibles que impulsan el flujo eficiente de valiosos recursos de vuelta a la cadena de producción.

DIRECCIÓN : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

DIRECCIÓN : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Red IPv6 compatible

Red IPv6 compatible