En el bullicioso corazón de las plantas de reciclaje y desguace, una fuerza colosal reina suprema: la trituradora de metales. Mucho más que una simple máquina destructiva, este coloso industrial es un pilar sofisticado del reciclaje moderno y la recuperación de recursos, convirtiendo montañas de metal desechado en valiosos productos reutilizables.

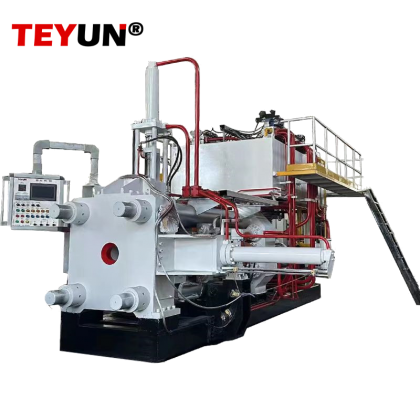

Imagine una máquina capaz de devorar coches enteros, electrodomésticos obsoletos, acero estructural y residuos industriales. Ese es el poder de una trituradora primaria de metales. En su núcleo se encuentra un rotor masivo de alto par que gira a velocidades vertiginosas. A este rotor se unen filas de martillos increíblemente duraderos y de movimiento libre, a menudo fabricados con aleaciones especiales resistentes al desgaste. A medida que la chatarra se introduce en la cámara de la trituradora (normalmente mediante cintas transportadoras), estos martillos producen impactos devastadores y repetidos. El metal se desgarra, cizalla y pulveriza contra las robustas barras rompedoras que recubren las paredes de la cámara.

¿El resultado? Objetos grandes y difíciles de manejar se reducen a fragmentos del tamaño de un puño o más pequeños, conocidos como chatarra triturada o "frag". Esta drástica reducción de tamaño es crucial. Libera diferentes materiales atrapados en elementos complejos (como el cableado de cobre de un automóvil) y crea una materia prima uniforme, esencial para un procesamiento posterior eficiente.

Pero la función de la trituradora no termina tras la fragmentación inicial. El material triturado se somete a un sofisticado proceso de separación:

1. Imán ferroso: Los potentes imanes superiores extraen sin esfuerzo fragmentos de hierro y acero (metales ferrosos), que forman la mayor parte de la mayoría de la chatarra.

2. Separación de no ferrosos: Las tecnologías avanzadas como los separadores de corrientes de Foucault separan metales no ferrosos valiosos como aluminio, cobre, latón y zinc.

3. Manejo de residuos: Los residuos no metálicos restantes ("pelusa": plásticos, caucho, espuma, vidrio, suciedad) se depositan en vertederos o se procesan cada vez más para una mayor recuperación de recursos o generación de energía.

¿Por qué es indispensable la trituración?

* Reducción de volumen: la trituración compacta drásticamente la chatarra, lo que ahorra costos masivos de almacenamiento y transporte.

* Liberación de Materiales: Libera diferentes metales y materiales unidos entre sí, permitiendo un reciclaje eficiente.

* Valor de mercado: El metal triturado, limpio y separado se vende a precios significativamente más altos que la chatarra mezclada y sin preparar.

* Imperativo ambiental: La trituración de metales es fundamental para la economía circular. Conserva los recursos naturales (mineral, energía, agua) y reduce drásticamente los residuos en vertederos y el impacto minero en comparación con la producción de metal virgen.

Las trituradoras de metal modernas son proezas de ingeniería robusta, equipadas con sofisticados sistemas de monitoreo, funciones de seguridad y tecnologías de supresión de ruido y polvo. Desde el humilde automóvil destinado a renacer como nuevas vigas de acero hasta el refrigerador obsoleto que produce sus valiosas bobinas de cobre, la poderosa trituradora de metal se erige como una fuerza poderosa y esencial: no solo desmenuza el metal, sino que transforma meticulosamente los desechos de ayer en los valiosos recursos del mañana, impulsando la sostenibilidad con una revolución arrolladora.

DIRECCIÓN : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

DIRECCIÓN : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

Red IPv6 compatible

Red IPv6 compatible